TL;DR

We were a crew of just two today but moved the chicken coops, harvested tomatoes and squash, tilled in the high tunnel, and prepared beds for planting with the crew tomorrow.

Trust And Verify

This isn’t the first time, but it’s still definitely new territory for me to be operating a very large tractor. To get in time on stuff like this, you either have to be formally trained via some school or informally as I am these days on a farm. I already learned the basics of operation last month, but since then have had very few chances to get more time in. Only when the timing is right…meaning that we have a need to prepare beds, that we’re not in a huge rush to plant as our immediate next crew task, and that there’s time for Jamie to maintain an on-call status in case anything needs his help…is me being on the tractor possible. So I’m grateful when it does.

In a prior life, in a corporate office, I once saw a sign that said “Trust but Verify” which always kind of irked me. It was the ‘but’, like a big fat butt rudely sat down in the middle between two very important things. “Trust AND verify” on the other hand served me very well for about 6 years between 2017 and 2023 when I worked for people that saw what I could do, saw how I worked, and saw that their bigger challenges demanded both. Trust takes time, but so does running around verifying things. Most relationships are built on verifications, then validations, then eventually trust. So I tend to work in such a way that at any point in time, people can verify what and how I’m doing it, then they can build their own confidence factors as they see fit. This is the quickest way to earn trust with those you work with.

Handing over tractor operations takes trust. Even if, in the very next moment, using a BCS to till a high tunnel bed results in a bit of field clog. The good thing is that we don’t need an extra wiggle wire and 5ft of irrigation line caught up in the tiller did no harm, just took about 5mins to de-clog. This is some of the hardest and most personally rewarding work I’ve done so I have to make every experience count.

Building a Mobile App Over the Winter

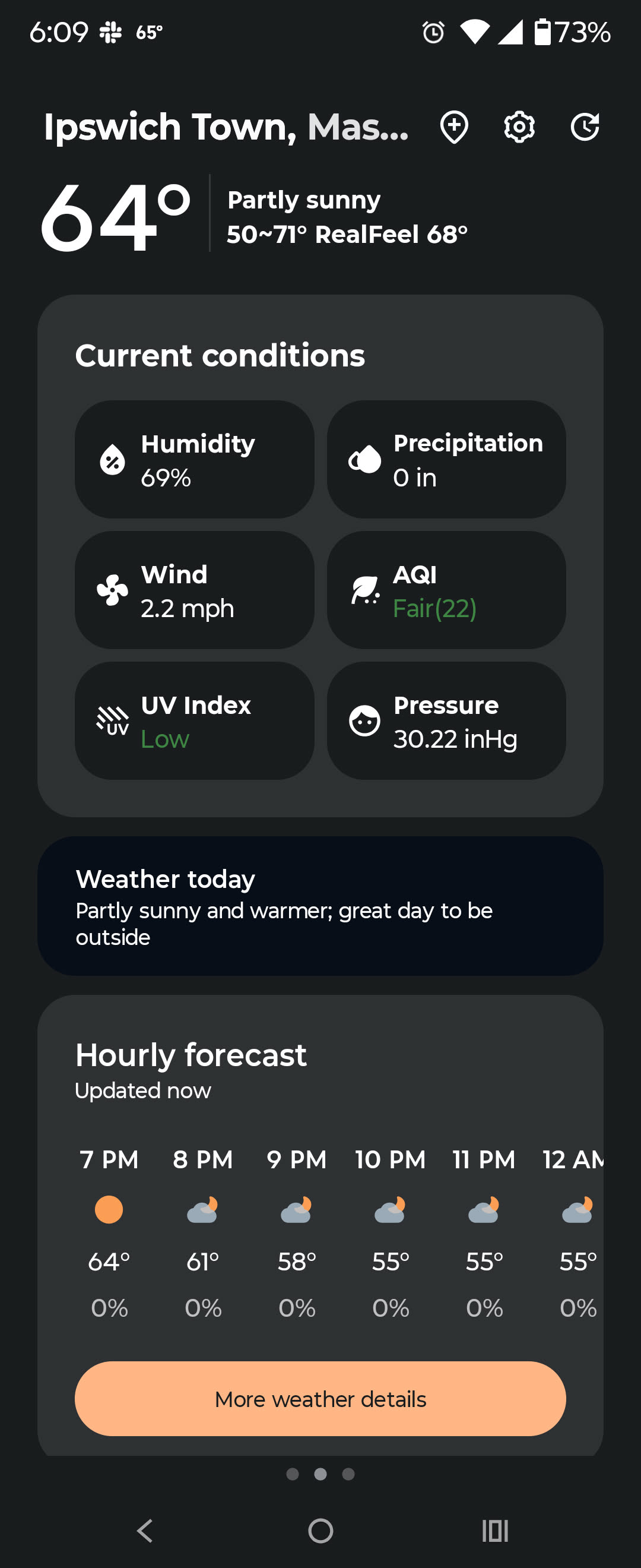

Towards the beginning of December, I’ll have about three months away from the farm to do other things. Some of that will be paid and some of it will not be. One of the ‘not paid’ things will be to build a mobile app for the first time in about 8 years, so I’m re-learning a bit of stuff. The good news is that my 25 years of tech experience really comes to the rescue when things don’t work as stated in docs. I anticipate cataloging and sharing parts of my journey through this process as well, but will likely do that elsewhere than this farming blog.

AI Summary from Field Notes

Part 1

Main Themes:

- Daily Farm Tasks: Harvesting, equipment operation, and field preparation.

- Collaboration with Jamie: Learning to use machinery with guidance and teamwork.

- Equipment and Machinery: Use of tractors, BCS (tiller), and specialized tools like the PTS system.

- Technical Learning: Understanding complex machinery (e.g., PTS, BCS) and their roles in farming.

- Efficiency and Problem-Solving: Addressing challenges like weed control, soil preparation, and equipment limitations.

Activities Performed by the Intern:

- Moved chickens and filled a tank.

- Harvested tomatoes.

- Prepared beds for planting (using a John Deere tractor).

- Operated a BCS (manual tiller) to clear rows under a high tunnel.

- Collaborated with Jamie to learn tractor and machinery operations.

- Documented processes (e.g., video footage of BCS use).

New Things Not Yet Encountered:

- BCS (Bare Ground Cultivator): A manual tiller used for rows under high tunnels.

- PTS System: A complex tractor system (likely a “Power Take-Off” or “Power Steering” system) for machinery.

- High-Tunnel Management: Understanding the unique needs of non-temperature-controlled greenhouses.

- Manual Labor Intensity: The physical strain of using the BCS for extended periods.

Questions and Future Research Areas:

- Efficiency of BCS: How effective is the BCS in rocky soil or longer rows?

- PTS System Functionality: How does the PTS system integrate with other machinery?

- Equipment Needs for High Tunnels: Are there other tools or methods for maintaining high-tunnel rows?

- Long-Term Use of BCS: How does repeated use of the BCS affect worker safety or productivity?

- Comparative Equipment: What are the pros and cons of using a full tractor vs. a BCS for high-tunnel rows?

Suggested Actions:

- Further Training with Jamie: To better understand the PTS system and tractor operations.

- Test BCS in Different Conditions: Document its performance in rocky soil, long rows, and varying weather.

- Document High-Tunnel Maintenance: Create a checklist or guide for tasks like row clearing and weed control.

- Evaluate BCS Longevity: Monitor the BCS’s durability and maintenance needs over time.

- Share Knowledge: Share insights on BCS use with other growers or through podcasts/recordings.

Part 2

Main Themes:

- Ecological Management: Identifying weeds, understanding cover crops (e.g., winter rye), and tracking the farm’s ecosystem for land management.

- Farm Planning: Rearranging fields, using landscaping fabric, and planning for the next growing season.

- Non-Logistical Interaction: Spending time with Jamie for personal conversations.

- Sustainable Practices: Using non-chemical methods to manage weeds and pests.

Activities Performed by the Intern:

- Collecting Summer Squash: Helped gather squash from multiple patches.

- Weed Identification: Took photos of weeds (e.g., pigweed, prickly lettuce, grasses, leek from winter rye) to identify species.

- Cover Crop Discussion: Discussed the role of winter rye as a cover crop for green manure.

- Water Management: Filled up pig water and prepared water for the next day.

- Field Discussion: Talked with Jamie about non-logistical topics.

New Things Not Yet Encountered:

- Specific Weed Species: Identified pigweed, prickly lettuce, and leek (possibly from winter rye).

- Cover Crop Ecology: Observed how winter rye naturally spreads in fields.

- Personal Interaction: Spending one-on-one time with Jamie, which is not a farm task but a personal activity.

Questions and Future Research Areas:

- Weed Species Identification: How to accurately identify specific weed species for targeted management.

- Cover Crop Impact: How winter rye affects field ecology and whether its spread is beneficial or problematic.

- Non-Chemical Weed Control: Effectiveness of methods (e.g., landscaping fabric, crop rotation) for reducing weeds without pesticides.

- Field Rearrangement: How to optimize field layout based on current weed and crop interactions.

- Ecological Tracking: Long-term monitoring of the farm’s ecosystem (bugs, weeds, soil health) for sustainable practices.

Suggested Actions:

- Document Weeds: Create a detailed list of identified weed species for future reference.

- Track Cover Crop Impact: Monitor how winter rye affects field productivity and weed competition.

- Plan Field Layout: Use data on weed distribution and crop needs to rearrange fields next season.

- Maintain Records: Keep a log of ecological observations (e.g., bug populations, weed types) for informed land management.

- Collaborate with Jamie: Schedule regular non-logistical check-ins to maintain personal and professional connections.

Part 3

Main Themes:

- Teamwork and Workload: The intern and Jamie work together, highlighting the advantages and limitations of a small team size.

- Routine Maintenance: Daily tasks such as cleaning buckets, animal chores, and moving chicken coops.

- Problem-Solving: Addressing the issue of a leaking tire in the new chicken coop and the need for a portable air compressor.

- Equipment Usage: Introduction and potential challenges of using a portable air compressor.

Activities Performed by the Intern:

- Cleaned all leftover buckets from last week.

- Completed chicken chores (including moving chicken coops).

- Addressed the flat tire issue in the new chicken coop by using a portable air compressor.

- Described the process of using the compressor (plugging it in, compressing air, and portability).

New Things Not Yet Encountered:

- Portable Air Compressor: A new tool used to inflate the flat tire in the chicken coop.

- Chicken Coop Design Flaw: The structural issue with the tire hole in the new coop.

Questions and Future Research Areas:

- How effective is the portable air compressor for regular maintenance tasks?

- How can the chicken coop’s tire issue be permanently fixed (e.g., repairs or replacement)?

- Are there alternative solutions to the tire problem in the coop?

- How does the small team size (two people) impact the efficiency of large-scale tasks?

Suggestions for Action:

- Repair/Replace the Chicken Coop Tire: Investigate or fix the tire issue to prevent future flats.

- Document Compressor Usage: Track how often the portable air compressor is used and its effectiveness.

- Train Team on Equipment: Ensure Jamie and the intern are familiar with the compressor’s proper use.

- Plan for Larger Projects: Consider how to manage larger tasks with a smaller team in the future.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: