TL;DR

We spent three hours moving chicken coops, harvested sunflowers, and planted lettuces. People are preparing to go back to school, student and staff colleagues alike, and the bees are just as busy as ever.

At home, another five pounds of tomatoes went in to the dehydrator, making my whole house smell like a sandwich shop. In other words, yum.

Amongst the Sunflowers and Bees

While cutting sunflowers, I noticed that the bees were just as busy as ever. They were buzzing around the flowers, collecting pollen and nectar, and coincidentally me to no worry at all. How methodically they work. I can only aspire to be as efficient and effective as they are.

Dehydrating Everything

Let me start by saying that I never meant to be like one of those all-natural, zero-preservatives MAHA nutters that John Oliver cracks jokes at. And I’m not…I just love good food that I can understand. How it grows, how it’s made, how it’s processed. I like to learn and know about things.

Working on a farm, there’s a bit of otherwise non-sellable produce that is fine eating but doesn’t look as good as the rest. As a farmer, you want to put your best foot forward. So when there are things that we won’t sell…like split or scarred tomatoes…they either go to the chickens and pigs or into the compost. That is, unless someone claims it.

Dehydrating Tomatoes

With the absolute joy that fresh tomatoes in season are, I’d rather take the 15 minutes to cut around the splits and cracks and little blemishes in order to reclaim otherwise 85% perfectly fine tomato mass and slice it thick for dehydrating. Most of the water leaves so that there is longer storage life. The flavors intensify. The color deepens.

Each tomato is different and thus each dehydration batch takes a little attention throughout the process, but for the most part it’s a ‘set it and forget it’ thing with a dehydrator. I was able to get a like-new Cosori dehydrator from a friend and have been trying out anything that comes from the farm. So far, the tomatoes are a huge win.

“So They’re Like Sun-Dried Tomatoes, Right?”

In the past week, I’ve been sharing them with people I think I can get an honest read from…family, co-workers, and people around town. Most often, the first thing people will respond with is “So they’re like sun-dried tomatoes, right?” Sure. Yes. Fine. Mapping to something known. Got it.

No, they’re not like sun-dried tomatoes. They’re dehydrated tomatoes. They’re not treated with sulfur dioxide and dried in the sun. They’re dried in a dehydrator. They’re not as intense in flavor as sun-dried tomatoes. They’re more mellow. Personally, I used to hate sun-dried tomatoes because they seem far too intense to use directly, like on a pizza or in a bread loaf.

Storing Dehydrated Tomatoes

Dehydrated tomatoes are usually dry packed, not packed in oil like their sun-dried cousins. They can be stored for up to a year in your pantry (if stored properly in an airtight container), or longer if done the same and frozen. I don’t think mine will last this long unless I do a lot of them while the getting is good in-season.

Since I don’t have a chest freezer (yet) and I plan to do this again next year, I’ll store most of mine in the pantry in a bag inside a jar, both airtight and away from sunlight. Some will also go into the freezer, double bagged and off to the side so that I can compare methods next fall as well.

Late Night Tomato Indulgence

The other night when I couldn’t sleep and wandered into the kitchen, I had this idea to wrap fresh cherry tomatoes in some of the dehydrated tomatoes. With a pinch of salt, it was…indulgent. At first the juice of the fresh tomato pops in your mouth and the taste of yesterday’s summer harvest is right there with you. But as you chew, the new tomato flavor subsides to the growing intensity of the dehydrated tomato, like a crescendo of flavor that’s both familiar and new at the same time.

I don’t think that this is for everyone, just the epicurus amongst us. It is very acidic and not for the faint of heart. It’s more for the epically-curious about the extremes of flavor that a single fruit or vegetable can bring to the table. Like I’ve written about potatoes, some vegetables don’t need much to elevate them to their greatest heights.

Weekend Spike Work

This weekend, I did find some time to add API endpoints to LLMBO matching that of Ollama’s out-of-box schemas. I even got streaming responses to work with a little attention to detail around HTTP chunking support. This enables me to point anything…including even Ollama tooling…to LLMBO and use it just the same as Ollama.

What this really enables for me is that everything in my infrastructure looking for an LLM can now use LLMBO without any changes to the code. This includes my own tooling like Autoscribe which uses Langchain Ollama libraries, but also third-party tools that I use like Karakeep that has experimental Ollama support.

LLMBO is primarily a dynamic router, managing concurrency and inbound requests with sessions so that I can scale it out as needed. It also prioritizes any backend agent with a GPU over that which doesn’t, but really in the future this scheduling will be done by a more sophisticated algorithm that understands the capabilities and capacity of each backend agent.

In the future, I want to add more features to LLMBO, such as better support for multi-modal inputs and outputs, and more advanced scheduling algorithms. I also want to add more observability (i.e. OpenTelemetry signals) to help with debugging and monitoring that I’m sure will be needed the more features and advanced behaviors are added.

I also want to make it easier for others to use and contribute to LLMBO, so it’s likely that I’ll be open sourcing it just as soon as I get to a minimum-viable (useful and stable) version.

AI Summary from Field Notes

Today’s notes have only one or two minor blips, mostly coming from a known issue with the LLM not really understanding that when I say ‘other people did X’, it should split out what I did vs. what they did as activities I performed.

Summary

Main Themes

- Farm Operations and Planning: Repositioning chicken coops, crop harvesting, and seasonal planting schedules.

- Seasonal Preparation: Fall planting (lettuce, bok choy) and winter squash planning.

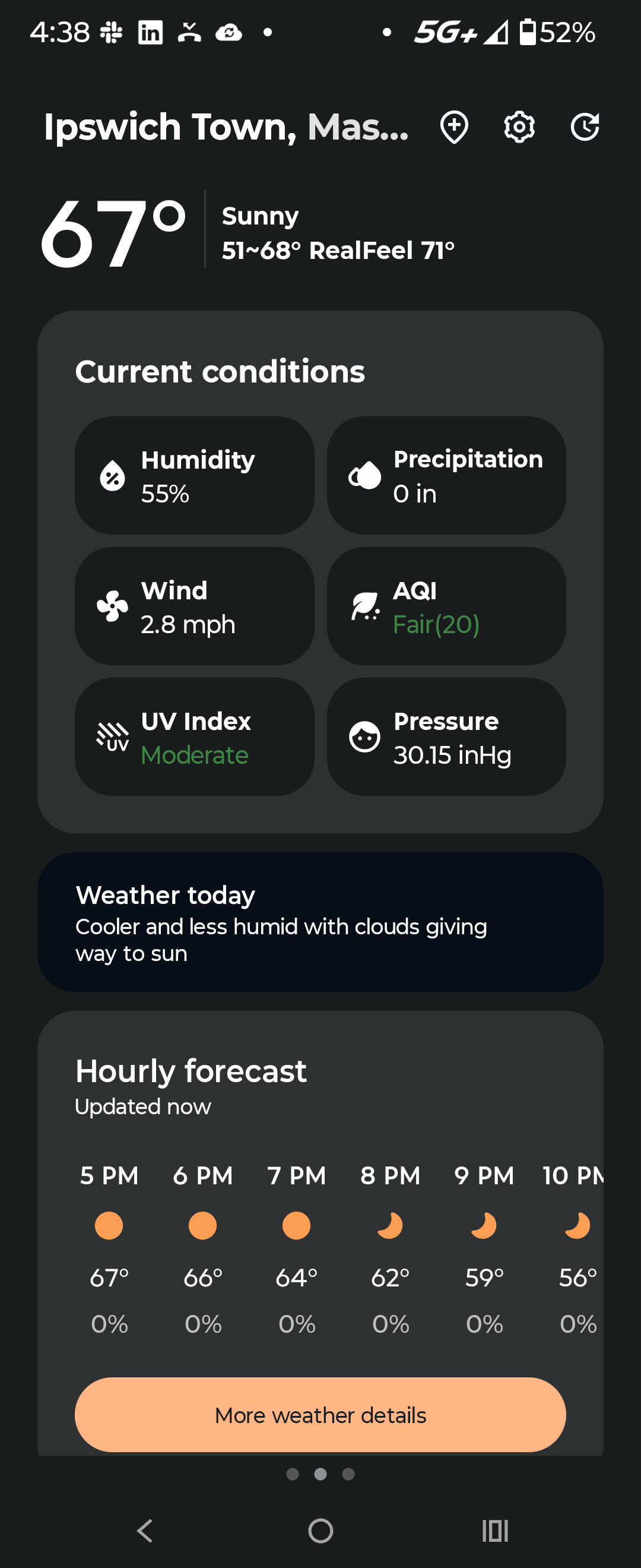

- Weather and Conditions: Cool, breezy weather (67–70°F) affecting work pace.

- Field Management: Expanding planting space by repositioning coops and optimizing field use.

Activities Performed

- Moved chicken coops 100 yards to free up space for future crops.

- Harvested 130 kale heads and stripped sunflowers for storage.

- Planted 4 lettuce rows (600–800 feet total) for fall.

- Loaded 98 lettuce cell trays into trucks for distribution.

- Collaborated with the team during lunch and post-lunch tasks.

New Things Not Yet Encountered

- Expanded planting space: Coops repositioned 50 feet further, creating 300 feet of new row space.

- Sunflower patches for CSA: A new sunflower patch for summer CSA.

- Winter squash planning: Preparation for fall squash share.

- Bok choy growth monitoring: Observing bok choy planted weeks prior.

Questions and Future Research

- Will repositioning coops improve field productivity?

- How will the new sunflower patch perform for the CSA?

- When will bok choy be ready for harvest?

- How to prepare for winter squash planting?

- Can coop movement be optimized for efficiency?

Suggestions for Action

- Monitor bok choy growth to determine harvest readiness.

- Assess new coop area for future crop planning.

- Develop a fall squash planting timeline and resource plan.

- Optimize sunflower patch care to ensure CSA yield.

- Document coop movement challenges (e.g., fence, hill) for future improvements.

Part 1

Main Themes

- Farm Operations and Planning: Movement of chicken coops, crop harvesting, and planting schedules.

- Seasonal Preparation: Preparing for fall planting (lettuce, bok choy) and winter squash.

- Weather and Conditions: Cool, breezy weather with a mild temperature range (67–70°F).

- Field Management: Expanding planting space by repositioning chicken coops and optimizing field use.

Activities Performed by the Intern

- Moved chicken coops: Replaced previous locations to free up space for future planting, moving them 100 yards around the field.

- Harvested kale: Collected 130 heads of kale.

- Harvested sunflowers: Stripped sunflowers and stored them in water.

- Planted lettuce: Planted 4 short rows of lettuce (approximately 600–800 feet total).

- Loaded and transported crops: Loaded 98 cell trays of lettuce into trucks.

- Collaborated with the team: Worked with others to complete tasks, including lunch and post-lunch activities.

New Things Not Yet Encountered

- Expanded planting space: Moving coops 50 feet further to create 300 feet of new row space for future crops.

- Sunflower patches for CSA: A new patch of sunflowers for the summer CSA.

- Winter squash planning: Mention of turning attention to winter squash for the fall share.

- Bok choy growth monitoring: Observing the growth of bok choy planted a few weeks prior.

Questions and Future Research Areas

- Effectiveness of coop repositioning: Will the new location for coops improve field productivity?

- Sunflower patch yield: How will the new sunflower patch perform for the CSA?

- Bok choy harvest timing: When will the bok choy be ready for harvest?

- Winter squash preparation: How to prepare for winter squash planting in the fall?

- Efficiency of coop movement: Can the process of moving coops be optimized in the future?

Suggestions for Action

- Monitor bok choy growth: Track its progress to determine harvest readiness.

- Assess new coop area: Evaluate the new space for future crop planning.

- Plan for winter squash: Develop a timeline and resources for fall planting.

- Optimize sunflower patch management: Ensure proper care and yield for the CSA.

- Document coop movement efficiency: Record time and challenges to improve future logistics.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: