TL;DR

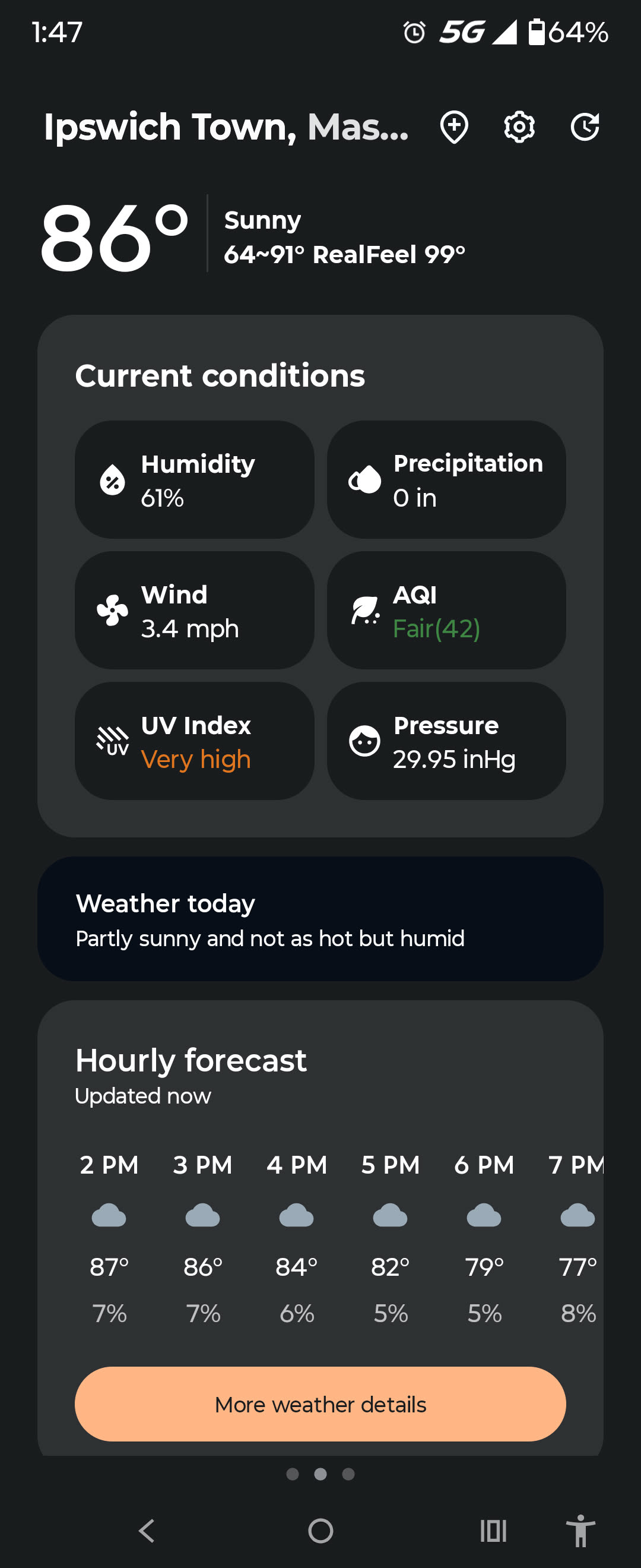

It was 90 degrees as we weeded and hoed, but this was much more bearable than yesterday. Napa cabbage harvested, basil pinched, and leeks completely weeded.

Weeding and Hoeing

This just has to be done when you can get to it, so we did. Most of the topsoil had already been baked by the sun over the past few days so the light weeds in the fennel and cilantro beds were easy to address with stirrup hoes. Not so much with the leeks, which even though we mulched with salt marsh hay a few months ago, still had plenty of weeds to deal with by hand.

This kind of work seems to go so much faster when you have 6 people working together instead of just two or three. Yes, it gets done faster, but the mental burden of how much more is left seems lighter as well.

Excuse Me, You Did What to Basil?

We also pinched off basil. Basil the plant, not some guy named Basil. As basil is a tender annual, it’s best to pinch it off at the seeding tip to encourage bushier growth and extend the harvest season. Doing this in my own garden this morning took about 5 minutes because I only grow about 2 dozen Thai and other varieties of basil plants per season. In a 200 foot row with 6-inch apart and three plants per spacing, this is 1200 plants. It took four of us about 30mins to do all of them.

Trading Pallets for Tote Bins

As the harvesting season comes in to full swing with nearly every week day having something to harvest, wash, and pack into tote bins for the walk-in refrigerator, every bin becomes sacred real estate for produce. There are very few not in use at any given time now.

In general, anything that touches the floor must be re-washed and sanitized. In the early season, we were using the smaller orange bins upside down in the fridge to stack green bins on because no produce (or bin carrying such) can touch the floor. They’re easy to move around, compact, and you can always rearrange if you need one or two to come out.

While this works in the early season when there’s less produce being harvested from the fields, there’s a point where it makes more sense to use the pallets instead. So we washed and sanitized the ground-level black pallets that the totes used to sit on outside, and moved them into the fridge instead. We reclaimed about 8 orange totes this way which is more than enough to help with the tight window of variance between harvest timing and tote availability.

Watering and Consolidating the Greenhouse

It was another day for multiple waterings throughout the day, but after mentioning on Monday that I was interested in starting to consolidate various trays and seedlings in the greenhouse, I got that job today. So I spent about 20 extra (hot, sweaty) minutes moving still-viable seeding trays to the front of the greenhouse and tossing otherwise fried trays into a pile for later deconstruction/composting.

There are still large sections that can be further consolidated, but it would take two people to do it efficiently since many of these sections fit nicely together on wooden ‘ladders’. Moving these by yourself would take at least twice as long as just getting another person to help, so that’s what I’ll suggest as a 30min task tomorrow so it’s all done for the season…at least until we start seeding some fall crops.

Sometimes, You Just Need to Simplify…Even with AI

Three weeks ago, I switched the summarization part of my daily notes from using Ollama3.2 to using Deepseek-R1. I had my reasons at the time, but only time could show that this was not worth it. However, after the last few days of mitigating the Deepseek-incurred hallucinations and over-thinking tirades in the summaries, I decided to look for a model which still had reasoning built in but did a much better job of the type of prompts and context I was providing.

I also had my hesitations about how and on what the Deepseek models were trained, not to mention all the political and ethical implications of using it. After seeing it devolve into different languages, both human and programming ones, to do something as simple as extract topics and takeaways from clearly articulated and thought-through field notes…I now understand how important it is to right-fit specific AI technology to specific tasks…and to develop experience and expertise in the field of operationalizing AI.

Let’s just say that some models, no matter how thoroughly you prompt them to use English, will always go back to their roots in the language they were trained on. And I don’t speak or read Mandarin, so diagnosing the origins of the hallucinations was more difficult than it had to be.

After running some trials against the existing langchain process with a different ‘reasoning’ model, I found that the qwen3:4b model was a better fit. We will keep a careful eye on its performance and make adjustments as needed. So for today, let me introduce you to my revised AI summarization process:

Summary

Final Consolidated Summary

Main Themes

- Weeding and Mulching: Managing leeks and basil, applying mulch (salt marsh hay) with challenges due to wind.

- Greenhouse Management: Watering seedlings, hardening off zucchini/squash in a cooler greenhouse.

- Sanitation and Pallet Use: Reusing pallets in the walk-in fridge for hygiene, replacing bins due to space constraints.

- Time and Labor Management: Tracking work hours, coordinating with the crew, and prioritizing tasks.

- Crop Preparation: Preparing seedlings for planting and ensuring they are ready for transplant.

Activities Performed

- Weeded leeks, addressing salt marsh hay and wind challenges.

- Applied 2-inch mulch layer (salt marsh hay) with uneven coverage.

- Watered greenhouse twice daily to acclimate seedlings.

- Moved seedlings to the greenhouse for hardening off.

- Cleaned and reused pallets in the walk-in fridge for produce storage.

- Closed field gate, assisted with pallet placement, and coordinated with the crew.

New Observations

- Florida Weave Trellis: A technique for supporting plants, noted as a new method.

- Reverse Hardening Off: Acclimating plants to outdoor conditions when the greenhouse is cooler than the outside.

- Pallet Hygiene: Using pallets in the fridge as a space-efficient sanitation solution.

Questions for Future Research

- How to improve mulch coverage despite wind interference?

- Is the current hardening off method (cool outside, warm greenhouse) optimal?

- Are pallets sufficient for hygiene, or additional measures (e.g., UV treatment) are needed?

- How to balance workload (weeding, greenhouse prep, pallet cleaning) to avoid burnout?

Suggestions

- Improve Mulch Application: Use windbreaks or adjust placement to minimize wind interference.

- Optimize Pallet Use: Explore alternative sanitation methods if pallets are insufficient.

- Refine Hardening Off Protocol: Test seedling acclimation in different temperature conditions.

- Streamline Workload: Prioritize urgent tasks (e.g., greenhouse prep) to avoid overwork.

This summary integrates key points from both documents, ensuring clarity, conciseness, and comprehensive coverage of all relevant aspects.

Part 1

Main Themes:

- Farm Work Routine: Daily tasks such as weeding, harvesting, and plant maintenance.

- Environmental Challenges: Extreme heat, weed management, and insect/bug presence.

- Plant Care and Timing: Importance of harvesting at optimal times to ensure plant quality.

- Observation of Nature: Encounters with rare or unexpected elements (e.g., flowers, frogs).

Activities Performed by the Intern:

- Weeding:

- Weeded leek patches (4 rows, ~200 feet each).

- Identified 30+ types of weeds.

- Harvesting Napa Cabbage:

- Harvested early in the day (before heat stress).

- Pinching Basil:

- Removed flower buds to extend leaf growth period.

- General Maintenance:

- Applied sunblock, bug spray, and lotion to combat heat.

New Things Not Yet Encountered:

- A Rare Flower: Observed a flower not seen before in the salt marsh hay area.

- A Frog: Spotted a frog, which the intern initially mistaken for a weed.

Questions and Future Research Areas:

- Weed Management: How to effectively manage 30+ weed species in leek patches?

- Heat Stress Impact: How does prolonged heat affect crop quality and worker safety?

- Frog Population: Is the frog a beneficial or invasive species? How does its presence affect the ecosystem?

- Optimal Harvesting Times: What is the ideal temperature range for harvesting napa cabbage?

- Basil Pinching Effectiveness: Does pinching basil extend leaf growth, or does it negatively impact plant health?

Suggested Actions:

- Develop a Weed Management Plan: Document weed types and create a targeted removal strategy.

- Monitor Frog Activity: Track frog presence to assess its role in the ecosystem.

- Implement Heat Mitigation: Introduce shaded areas or cooling techniques for workers.

- Test Harvesting Times: Record crop quality at different times of the day to optimize harvesting schedules.

- Educate on Plant Care: Train staff on the benefits of pinching basil and other plant maintenance techniques.

Part 2

Main Themes

- Weeding and Mulching: Weeding leeks, applying mulch (salt marsh hay), and managing mulch application challenges (wind, uneven coverage).

- Greenhouse Management: Watering the greenhouse, hardening off plants for zucchini/squash, and managing greenhouse temperature.

- Sanitation and Pallet Use: Cleaning and reusing pallets in the walk-in fridge to maintain hygiene for produce storage.

- Time and Labor Management: Tracking time spent on tasks, coordinating with crew, and prioritizing work (e.g., weeding, greenhouse watering).

- Crop Preparation: Preparing seedlings for planting (zucchini/squash) and ensuring they are ready for transplant.

Activities Performed

- Weeding: Finished weeding leeks, despite challenges with salt marsh hay and wind.

- Mulch Application: Applied a 2-inch layer of salt marsh hay, acknowledging uneven coverage.

- Greenhouse Watering: Watered the greenhouse twice daily (morning and evening) to prepare seedlings for planting.

- Hardening Off: Moved seedlings to the greenhouse for acclimation, noting the cooler outside temperature.

- Pallet Sanitation: Cleaned and reused pallets in the walk-in fridge to avoid floor contact with produce bins.

- Field Management: Closed the field gate, assisted with pallet placement, and coordinated with the crew.

New Things Encountered

- Florida Weave Trellis: A specific method for supporting tomato plants, though the intern was reassigned from this task.

- Hardening Off in Reverse: The process of acclimating plants to outdoor conditions when the greenhouse is cooler than the outside.

- Pallet Sanitation: Using pallets in the walk-in fridge for hygiene, replacing bins due to space constraints.

Questions and Future Research

- Mulch Application Efficiency: How to improve mulch coverage despite wind interference.

- Hardening Off Techniques: Whether the current method (cool outside, warm greenhouse) is optimal for seedlings.

- Pallet vs. Bin Sanitation: Whether the pallet system is sufficient for hygiene or if additional measures are needed.

- Time Allocation: How to balance tasks (weeding, greenhouse watering, pallet cleaning) to avoid overwork.

Suggestions

- Improve Mulch Application: Use windbreaks or adjust mulch placement to minimize wind interference.

- Optimize Pallet Use: Explore alternative sanitation methods (e.g., UV treatment) if pallets are insufficient.

- Refine Hardening Off Protocol: Test seedling acclimation in different temperature conditions.

- Streamline Workload: Prioritize tasks based on urgency (e.g., greenhouse prep over weeding) to avoid burnout.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: