TL;DR

In the morning I put together items for the general store delivery, then for the rest of the day we worked on constructing an winter enclosure for the pigs. It was a cold and smelly afternoon, but still a good day nonetheless.

Delivering Even After the Season’s Over

Every other day or so, we’re delivering produce to the new general store in Essex. This means we have to gather up amounts of items, some as simple as a green bin from the walk-in like egg dozens, others requiring more work like cleaning onions and packaging up leafy greens. We weight bulk items and count things already bunched like kale and salad turnips.

About store stuff…everything has to look big and pretty. For every one fat, pristine leek or pumpkin there are a few other perfectly fine but otherwise not store-quality specimens that are just as good. We also bundle smallish out-of-season produce such as tatsoi heads and red kale bunches when needed to make store-worthy sellable items. In the season, we use everything for the CSA because that’s what the farm shares are about…the best of what’s representative of our farm. However, making things look extra pretty and sorting for only the biggest first, takes more time than putting summer and fall share bags together.

If we delivered regularly to restaurants, we’d also have to do similar preening. Chefs don’t want golf-ball-sized onions because it’s the same amount of work to peel and chop them as it is to peel and chop larger ones that yield more usable insides. Two dozen pencil-thick carrots in a bunch might delight the home CSA member from time to time, but aren’t what the saucier needs when making gallons of stock or during mise en place for rapid-fire vegetable sauté that evening.

As boutique food goes, the store gets the best of what’s available, particularly easy in this late time of year since the fall share ended weeks ago and very little is left in the fields. But next year too, it will be the same, though just because the ‘best’ stuff is at the store doesn’t mean the shares will get any less than the amazing produce they’ve been getting for years.

New Digs for the Pigs

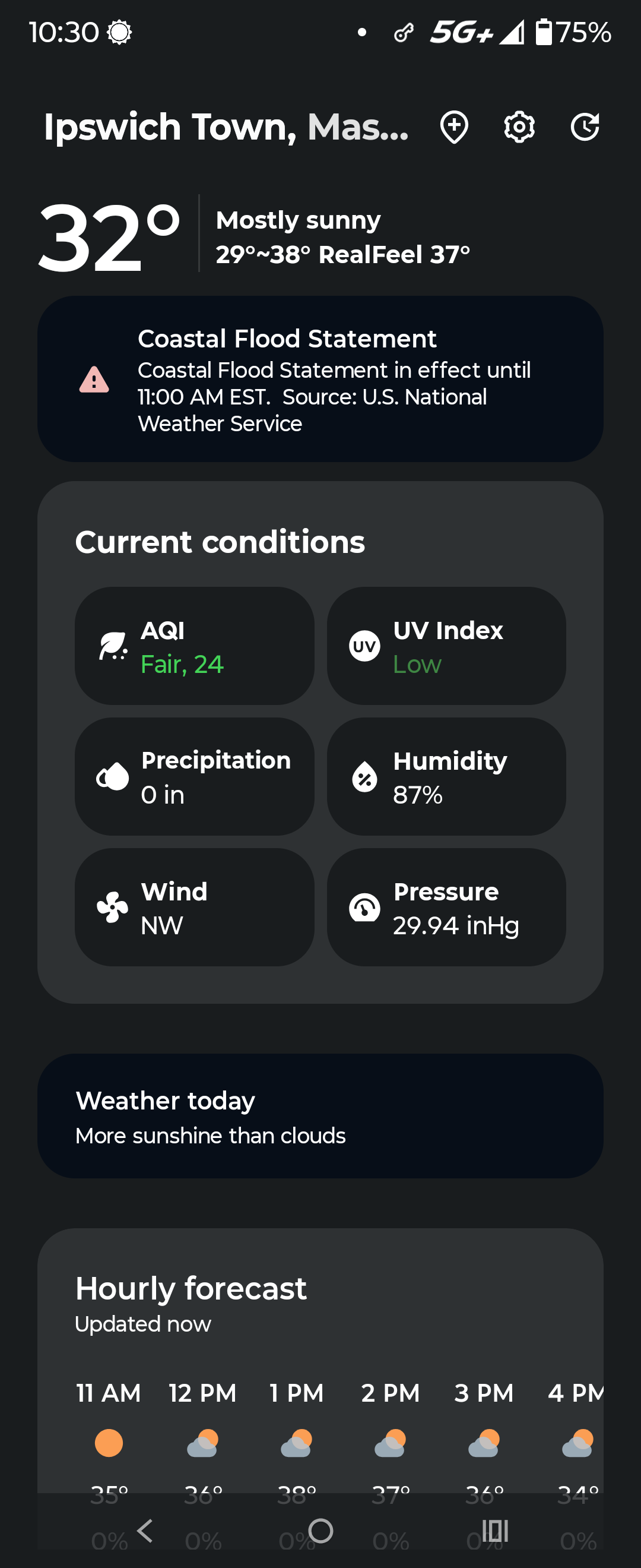

When we got back from delivery at around 10:30am, we started gathering tools and materials needed to construct a new winter pen for the pigs. In the summer and the fall, simple A-frames and plywood overhead in places was good enough, but now the nights are getting colder and the snow is starting to fall. These twelve pigs have been with us since late May and will leave us in late January, some bigger than others, but on average about 275lbs each.

Jamie is one of the kindest and most patient livestock caretakers I’ve ever met. Working with these creatures, some days it’s as easy to feel a sense of responsibility and sympathy as other harder days where you simply want to curse at your boot for getting stuck in the muck…which there is a lot of, mixed with urine and shit. Because of the wet fall weather, mud turns to sludge and inevitably there are places where it pools and freezes over, particularly near the water bucket.

Now, these piggies have plenty of room, fresh hay (not for long), even some skylights in the back we constructed from two leftover greenhouse polycarbonate panels. It’s not airtight, or should be for that matter, airflow is important too, but the wind isn’t bad up at the top of the woodsy hill with all the understory and brush surrounding the space. But piled up together, this should keep them quite cosy throughout December and January. This was a lot of work…about 5 hours total…and ‘not glamorous’ as I put it at one point. Even with long sleeved jacket and gloves, still not an inch of me lacked the grime, and Jamie was so much more so than me since his nature is to do the worst part of a job rather than letting someone else do it instead.

It’s not the smell that bothers me at this point…it’s the idea that pig biology is so close to ours, filth begets disease, and it gets everywhere if you’re not super careful. We wash our boots off outside and switch shoes and also often change clothes between piggy and veggie tasks frequently. We scrub our hands and arms thoroughly…I personally use orange industrial hand cleaner and slightly-too-hot water which seems like most effective way to reset my senses until shower time at home. It all requires steadfastness and attention to operating procedure to remain as safe as animal care is on this farm and we have a really good teacher.

AI Summary from Field Notes

Notwithstanding the point about ‘pig…productivity’ and the misunderstanding about permanence of the pig pen (both because they’ll go to slaughter in a few months and we tend to move them around at least twice a year anyway), the LLM-driven summary of today’s field notes gets an A-minus grade because:

- It grouped the activities into the two major projects of the day,

- It suggests observe pigs in the new shelter’, which we do to make sure the new fencing and shelter are working properly, not necessarily to ‘ensure comfort and reduce stress’.

As I think about what kind of documentation I would add to custom embedding or RAG/agent source materials to better inform these kinds of summaries, I realize how no one is really capturing in depth these details, certainly not many people in volume enough to have a meaningful impact on generic off-the-shelf LLMs like the one used for the following summary:

Summary

Final Summary

Main Themes

- Farm Operations & Logistics: Preparing and delivering produce to the general store in Essex.

- Animal Welfare: Constructing a permanent pig pen to protect pigs from cold weather and snow.

- Seasonal Challenges: Impact of freezing temperatures on crop harvestability and the need for protective measures.

- Collaboration: Working with Jamie to complete tasks, including heavy labor and coordination with the store.

Activities Performed

- Produce Delivery:

- Packaged eggs, mizuna, leeks, salad turnips, parsnips, broccoli rabe, and kale for the store.

- Delivered the order, unloaded, and added additional mizuna to the store display.

- Pig Pen Construction:

- Built a shelter using pallets, plywood, polycarbonate panels, and electric fencing.

- Cleared mud and debris from the pig area and ensured the enclosure was accessible.

- Post-Work Tasks: Cleaned up after the day’s work, including removing mud and washing.

New Things Encountered

- Mizuna Popularity: The store now heavily relies on mizuna, a leafy green, which became a key product after initial misunderstanding.

- Incline Design: The pig pen is built on an incline to prevent water pooling.

- Polycarbonate Panels: Used for the pig pen, possibly for durability or insulation.

- Cold Weather Impact: Remaining crops in the fields are at risk due to freezing temperatures, requiring planning.

Questions for Future Research

- How will the new pig pen affect pig health, behavior, and productivity in extreme weather?

- Can remaining crops be salvaged, or will they need to be stored or sold at a discount?

- Are pallets and polycarbonate panels suitable for long-term use in the pig pen?

- How will increased mizuna demand influence future harvest planning and storage?

Suggestions for Action

- Monitor Pig Behavior: Observe pigs in the new shelter to ensure comfort and reduce stress.

- Evaluate Crop Survival: Check remaining crops for viability and consider frost protection methods.

- Document Shelter Design: Record the incline and materials for future reference or replication.

- Plan for Winter: Develop strategies for crop management, including storage or alternative markets.

- Train Team: Ensure Jamie and others understand the new pig pen layout and seasonal tasks.

Part 1

Main Themes

- Farm Operations and Logistics: Preparing and delivering produce to the general store in Essex.

- Animal Welfare and Shelter Construction: Building a permanent pig enclosure to protect pigs from cold weather and snow.

- Seasonal Challenges: Impact of cold weather on crop harvestability and the need for protective measures.

- Collaboration and Teamwork: Working with Jamie to complete tasks, including heavy labor and coordination with the store.

Activities Performed by the Intern

- Prepared and Delivered Produce:

- Packaged 24 dozen eggs, 20 containers of mizuna, 15 pounds of leeks, 20 salad turnips, 15 pounds of parsnips, 10 broccoli rabe bunches, and 13 kale bunches.

- Delivered the order to the general store in Essex.

- Unloaded the delivery and added additional mizuna to the store display.

- Constructed a New Pig Pen:

- Used pallets, plywood, and polycarbonate panels to build a shelter for pigs.

- Installed an electric fence and ensured the enclosure was accessible for pigs.

- Helped with heavy labor, including clearing mud and debris from the pig area.

- Post-Work Routine:

- Cleaned up after the day’s work, including removing mud and washing in the shower.

New Things Not Yet Encountered

- Mizuna Popularity: The store now heavily relies on mizuna, a leafy green, which was initially misunderstood but has become a key product.

- Incline Design for Drainage: The pig enclosure is built on an incline to prevent water pooling inside the shelter.

- Polycarbonate Panels: Used for the pig pen to mimic greenhouse materials, possibly for durability or insulation.

- Cold Weather Impact: Remaining crops in the fields are at risk due to freezing temperatures, requiring further planning.

Questions and Future Research Areas

- Long-Term Shelter Effectiveness: How will the new pig pen affect pig health, behavior, and productivity in extreme weather?

- Crop Viability in Cold Weather: Can remaining crops be salvaged, or will they need to be stored or sold at a discount?

- Sustainability of Materials: Are pallets and polycarbonate panels suitable for long-term use in the pig pen?

- Market Trends: How will the increased mizuna demand affect future harvest planning and storage?

Suggestions for Action

- Monitor Pig Behavior: Observe the pigs in the new shelter to ensure they are comfortable and not stressed.

- Evaluate Crop Survival: Check remaining crops for viability and consider frost protection methods (e.g., covers, windbreaks).

- Document Shelter Design: Note the incline and materials used for future reference or replication in other areas.

- Prepare for Seasonal Changes: Develop a plan for winter crop management, including storage or alternative markets.

- Train Team on New Procedures: Ensure Jamie and others understand the new pig pen layout and seasonal tasks.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: