TL;DR

We harvested carrots and lots onions, dealt with an ornery gator, then packed up to go to market. The gator needs a new starter most likely and chores will be a pain until it gets one.

Forking Carrots

Since it was already a warm, soon-to-be hot again day, we started out by harvesting carrots. The pitch fork we purchased a month ago from a local hardware store simply just doesn’t keep up with the rocks in the soil, usually bending an outside tine or two every 50 feet or so. We can bend it back, but the more we do, the more it shows how not-hardened the metal is. I think we should bring it back and ask for a refund.

Even when you do get a good pitchfork’s worth of soil up about 2-3 inches from the carrot line, the soil can still be too hard to expect to pull carrots out of without losing the tops in the process. So sometimes I’ll go along and do the other side of the same row with a hand pitchfork which seems to do the trick.

The Onions Are Here!

It seems like only yesterday when we planted these onions, but really it was April 29th, almost exactly 3 months ago. We pulled one of six 300-foot rows in the dry fields today then spread them into trays used to dry cure them over the next week or so. This process will repeat until the end of August at least, so CSA customers have a steady supply of onions to look forward to. We are now one-third of the way through the onion harvest, considering that the Alise Craig fresh onions from the main field are all harvested now too.

This weekend I made Pico de Gallo from the fresh onions, greenhouse tomatoes, hot pepper, and field cilantro all coming from the farm. With a squeeze of lime and a pinch of salt and pepper, it was ‘gas’ as the younger generation on the crew said. It was also ‘fire’ because I added half a Hungarian Wax pepper, then promptly forgot to not rub my eye with the same fingers for a few days after touching them (no, I did not wear gloves when cutting it up).

But regarding the onions…they are a lot of work, trimming, planting, weeding, harvesting, and drying…but well worth it.

Fixing a John Deere Gator

Today the starter on the gator finally stopped working. It’s been a bit ornery for a while, but it gets used a lot every day. Compared to the other Gators on the property, this one is the oldest with many miles on it. It’s pretty essential to getting around to the pigs and chickens for morning and evening chores, so being stuck down at the chickens unusable is not ideal.

We looked at it for a little while today, tried a few things. Like many folks with boats who I’ve witnessed tap the starter to get it going again, we tried that too but to no avail. We checked connections, but everything else electrical seemed fine. Usually in this circumstance, we would call over to the guy on the landscaping crew with automotive background to come help fix it, and we might have to do that or even call a service tech. But like many things on the farm, we also could try to fix it ourselves.

If we were to try to DIY the fix, it would be a time-consuming process, since this model of Gator (and more recently many models of John Deere equipment) make some of the more common repairs difficult to access. Also, the starter might only need a repair kit or might need to be replaced entirely…you just don’t know until you get it open and we don’t really have the bench equipment to verify a repair like that vs. a replacement. The repair kit is around $50 whereas the replacement starter is $150, but even as cost-conscious as a farm budget needs to be, I think from a time and timing perspective it makes more sense to replace the entire starter assembly.

I hope I get a chance to help on the gator repair. I don’t have a ton of automotive experience, but I want to gain some for common farm equipment like this whenever I can. I AM very mechanically and electrically inclined, so I think I could at least be a helpful part of the repair process if they still chose to keep it in-house.

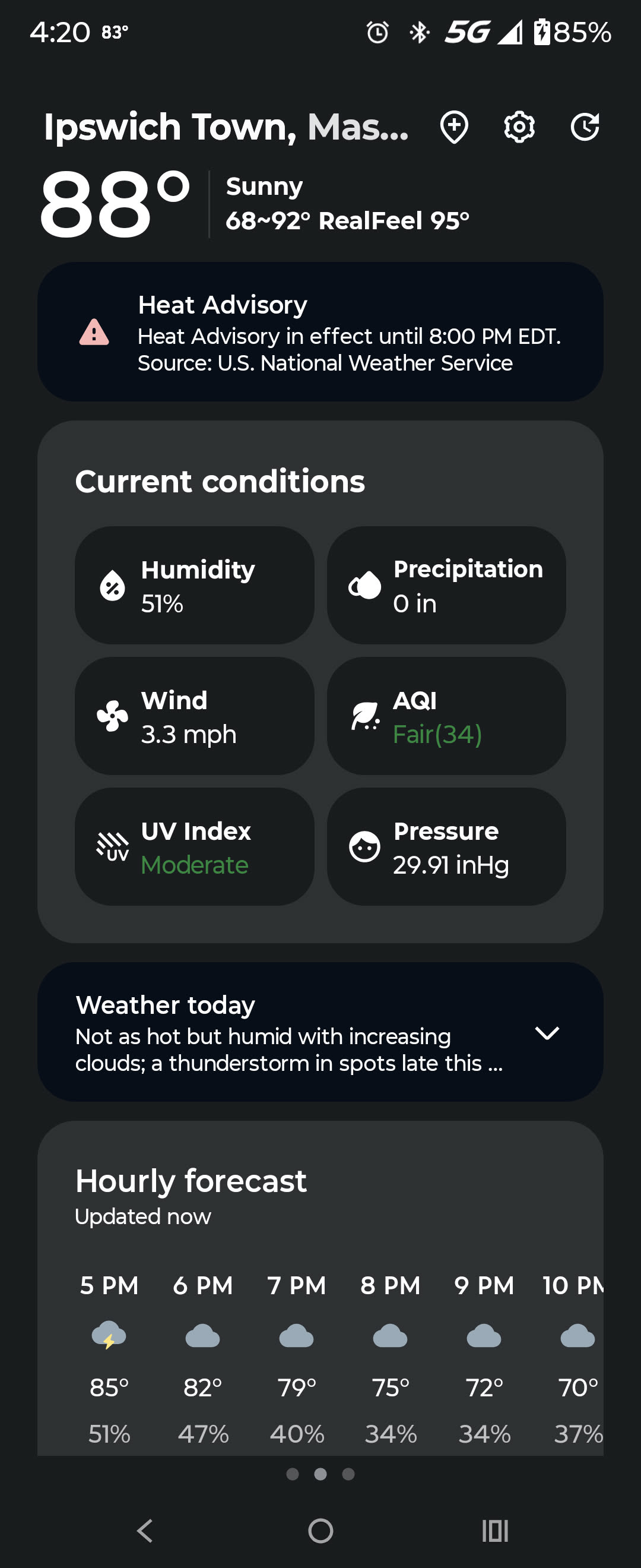

Cooler in the Next Few Days

The forecast for the next few days is for cooler weather and some spots of rain, but you never know what will actually happen to specific fields in hyper-specific locations. This is why it’s important to inspect crops, typically while doing something else like moving irrigation or harvesting, to keep eyes out for unexpected damage and growth rates.

The better the weather, the more we tend to do outside. Some days are buggier than others, but I’d rather be outside turning crops into produce than twiddling with inside activities. The gator repair might have to be done where it is in the field, and if so, I hope we bring one of the tents along.

How Much Can AI Do to Help Repair Equiptment?

In a world where ‘Youtube University’ makes people feel like they can do anything, it’s important to remember that AI is still a tool, not a replacement for human expertise. While AI can provide insights and suggestions, it’s up to us to apply those insights in a practical and safe way.

Unlike my homelab AI, platforms like ChatGPT tend to aggregate your queries into a sort of model of you, the user. Recently, Sam Altman of OpenAI basically admitted to zero-privacy when it comes to users’ data, which should be a person’s default assumption when using a free and/or SaaS product anyway.

From time to time, I will use ChatGPT to compare responses with my homelab processes and other AI platforms to see how they handle similar queries. As you can see, while somewhat helpful, ChatGPT can only go so far until you provide it more and more specific information about your circumstances, such as in this case the exact model of the gator. At some point, I imagine a law suit between John Deere and its consumers will include information about what they Googled or asked ChatGPT about custom repairs.

For now, I will continue to use my homelab AI for more specific tasks and rely on ChatGPT for general queries. And as always, my personal AI generates the following summaries for free and without any privacy concerns:

AI-generated Summary from Field Notes

Final Consolidated Summary

Main Themes:

- Harvesting & Crop Management: Celery, carrots, onions, and potatoes were harvested, processed, and stored.

- Volunteer Involvement: A volunteer family assisted with onion harvesting and setup.

- Equipment Challenges: A faulty gator (four-wheel tractor) required repair, impacting workflow.

- Animal Care: Pigs, chickens, and egg collection were managed.

- CSA Logistics: Two separate pickups with different trucks required coordination.

- Weather Impact: Extreme heat influenced work schedules and safety.

Key Activities:

- Harvested and transported crops.

- Dried onions using trays, sawhorses, and ladders.

- Fixed and repurposed the gator for animal chores.

- Coordinated with volunteers for crop tasks.

- Managed CSA pickups, including member assistance.

- Monitored animal health and egg collection.

New Experiences (Not Yet Experienced):

- Gator Repair: Dealing with an old, malfunctioning gator.

- Onion Drying Setup: Using trays, ladders, and sawhorses for drying.

- Volunteer Coordination: Managing a group for crop tasks.

- Animal Care Routines: Regular checks for pigs and chickens.

- CSA Pickup Management: Handling two separate pickups with varying logistics.

Questions for Future Research:

- How to efficiently repair or replace the faulty gator?

- What is the optimal method for drying onions in the shed?

- How to better integrate volunteer help into crop schedules?

- How to manage crew shortages during CSA pickups?

- How to adapt workflows for extreme heat conditions?

Suggested Actions:

- Gator Repair: Contact the landscaping crew for assistance.

- Onion Drying: Standardize tray, sawhorse, and ladder setup.

- Volunteer Training: Provide clear instructions for the volunteer group.

- CSA Coordination: Adjust schedules or allocate additional help during pickups.

- Weather Adaptation: Use shade structures or adjust work hours for heat.

This summary captures the critical elements of the original content, ensuring clarity and conciseness while maintaining all key points.

Part 1

Main Themes:

- Harvesting and Crop Management: Celery, carrots, and onions were harvested and processed.

- Volunteer Involvement: A volunteer family assisted with onion harvesting.

- Equipment Maintenance: A faulty gator (four-wheel tractor) required repair.

- Animal Care: Pigs, chickens, and egg collection.

- CSA and Market Logistics: Two CSA pickups (Gloucester and Ipswich) and market preparation.

- Weather Impact: Extreme heat influenced work timing and shade use.

Activities Performed by the Intern:

- Harvested celery and carrots, transporting them to the barn.

- Assisted with onion harvesting, including a 300-foot row of red onions.

- Dried onions in the shed using trays and sawhorses.

- Packaged potatoes into one-pound bags.

- Attempted to repair a faulty gator (failed in the field).

- Borrowed a gator for animal chores (pigs, chickens, egg collection).

- Helped with CSA pickups, including transporting and assisting members.

- Coordinated with a volunteer family for onion tasks.

New Things Encountered (Not Yet Experienced):

- Gator Maintenance: Dealing with an old, faulty gator and its repair logistics.

- Onion Drying Process: Using trays, sawhorses, and ladders to set up drying equipment.

- Volunteer Coordination: Managing a volunteer group for crop tasks.

- Animal Care Routines: Checking pigs, chickens, and collecting eggs.

- CSA Pickup Logistics: Managing two separate pickups with different trucks.

Questions and Future Research Areas:

- Gator Repair: How to efficiently repair or replace the faulty gator.

- Onion Drying Efficiency: Optimal methods for drying onions in the shed.

- Volunteer Workflow: How to better integrate volunteer help into crop schedules.

- CSA Pickup Coordination: How to handle crew shortages during pickups.

- Weather Impact: How to adapt workflows for extreme heat or humidity.

Suggested Actions:

- Gator Repair: Contact the landscaping crew for assistance with gator repairs.

- Onion Drying Process: Document and standardize the setup of trays, sawhorses, and ladders.

- Volunteer Training: Provide clear instructions for the volunteer family to ensure consistent crop support.

- CSA Pickup Planning: Adjust schedules or allocate additional help during peak pickup times.

- Weather Adaptation: Use shade structures or adjust work hours to mitigate heat stress.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: