TL;DR

We harvested chard, tomatoes, lots of cabbage, onions, and potatoes. We also planted scallions and hoed so many fresh rows. New members of the farm crew too.

In my research and homelab work, I’ve been pushing the art of summarization on multiple fronts…learning what inputs, what context, what prompts and issues make up a truly accelerating the feedback harvesting loop.

Tis the Season to Be Harvesting

There so much coming out of the fields we have been planting, weeding, and watering for months now. It’s an amazing feeling to know that the work put in earlier in the season pays off, but as usual only so with a great deal of continued effort.

Morning Sanitization

Most mornings, we start by loading up the truck with cleaned and sanitized round ‘blue bins’ (55 gallon plastic drums sawed in half with handles added). These bins are super rugged, large enough to bother bringing out to the fields for collecting crops, and easy to wash. They can also double as small wash basins when either the 30 gallon wash basin up at the barn is busy with other produce or we’re collecting root crops like beets and carrots that would otherwise dirty up the basin wash water prematurely.

In-field Coarse Pruning

For harvesting crops that need to be chopped in the field such as lettuce heads and cabbages, we use yellow-handled broad knives (see today’s photo reel) which serve a variety of uses, but are sharp enough to do a good job on the crops while not being so sharp that a light miss causes skin damage. These are also sanitized throughout the day just like the harvesting bins.

Much of the harvesting process involves extracting the part of the crop worth putting in the blue bins and casting off any damaged or weak parts of the plant. Sometimes the weather and sun permits precision pruning right in the field, but when it’s very hot or there’s a rush-order on getting the produce out and up for washing the in-field pruning is rough and can be dialed in later at the washing station.

With cabbage, the ‘chop’ at the base is well above the soil line since much of the outer leaves are either already insect damaged or would fall of anyway in the transportation and packing processes, so we leave those parts in the field for the next till-in by the tractor.

Wash Station Fine-pruning

Up at the barn, there’s also always buckets near the washing station for additional cast-off vegetable matter that either goes to the pigs at the end of the day or otherwise the compost pile. If it grows in the field, it’s worth going to use elsewhere if it doesn’t go to customers. There are strict rules to keep certain buckets at the barn vs. other containers that are used to feed or water animals.

Some produce, particularly delicates with an exposed stem at the base like celery and lettuces, require a lot of ‘fine-tuning’ (not unlike AI-driven systems) to result in outcomes that are worth the consuming. Each farm shows their balance of time-spend (and thusly attention to detail) in the produce they offer.

On a Personal Note

When I go to a farmers market or (more dreaded in-season) the grocery store, I look at the whole product…the tops, the stalks, the stems, the fruiting body, the base, the label and origin…because I intend to use the whole thing.

I’m not ‘picky’ about imperfections like a normo-consumer be, but I do want to know what I’m buying and putting in my eat-hole. I wash everything before I eat it because I know that even on a super-clean farm, you never know what sweated or sneezed on your produce during and after transport.

Work on a farm, maybe also a restaurant back-of-house, and you’ll never go back to assuming that all food is safe just because it was (or despite being) provided to you “looking pretty”.

New Members of the Farm Crew

While most of the farm crew are there multiple days a week, there are a few new faces this week. Like most mundane, repetitive tasks around the farm like weeding or bunching onions, it’s a great chance to get to know them and practice one’s listening skills. Students and academics workers are in particular are always fun to listen to for the few months in the summer they’re around until the fall semester begins.

I’m also very happy to see when new people don’t automatically plug in their earbuds or spend their time on their phone instead of engaging with the people around them. Looking for “what’s next” or “how can I help others’ work go faster” is a good thing in new farm crew members.

Artificial (Lack of) Intelligence?

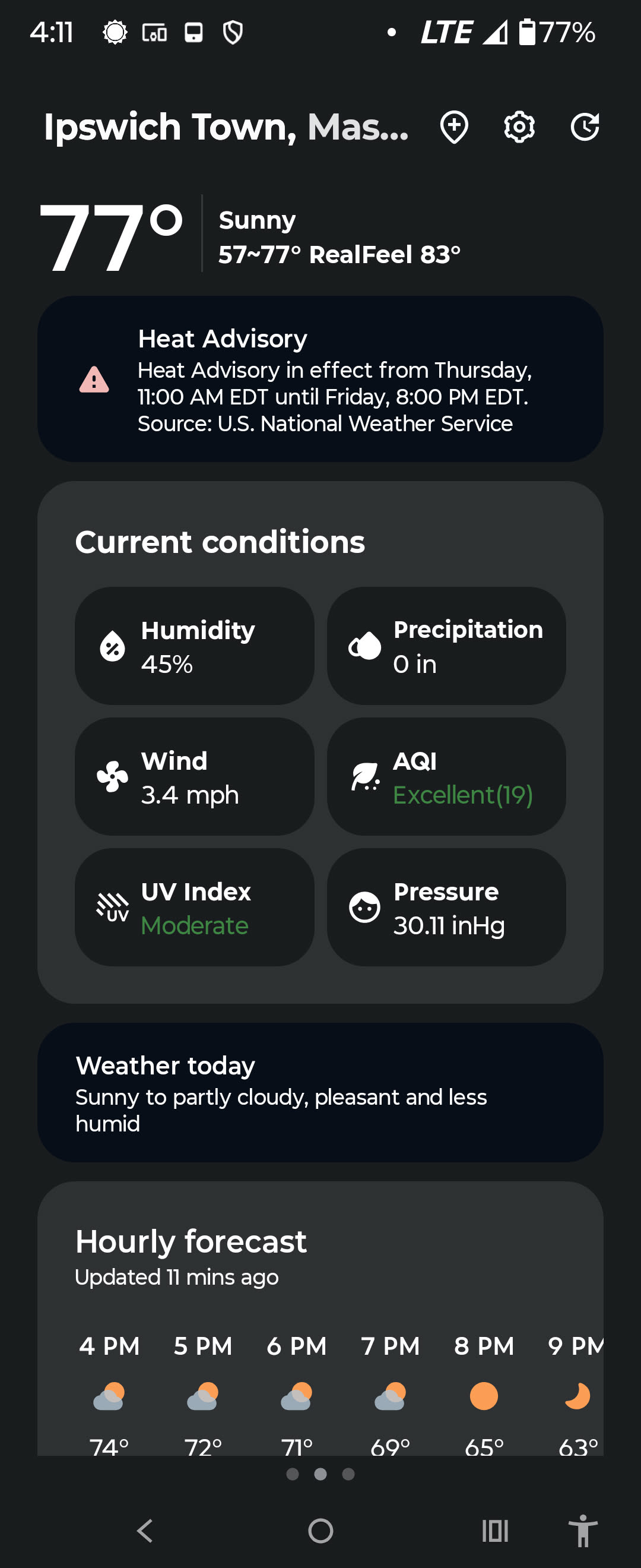

Unlike a good farm crew member, my AI summarization process isn’t itself very intelligent or empathetic to my own time-crunches and priorities in the morning. Especially on the days that I’ve left the blog writing to the next day, as I wake up early to absorb some coffee, select images and write this content, and maybe prepare to leave the house before the other members of my family are rushing to do so as well, its on these kinds of days that something in the process decides not to work smoothly.

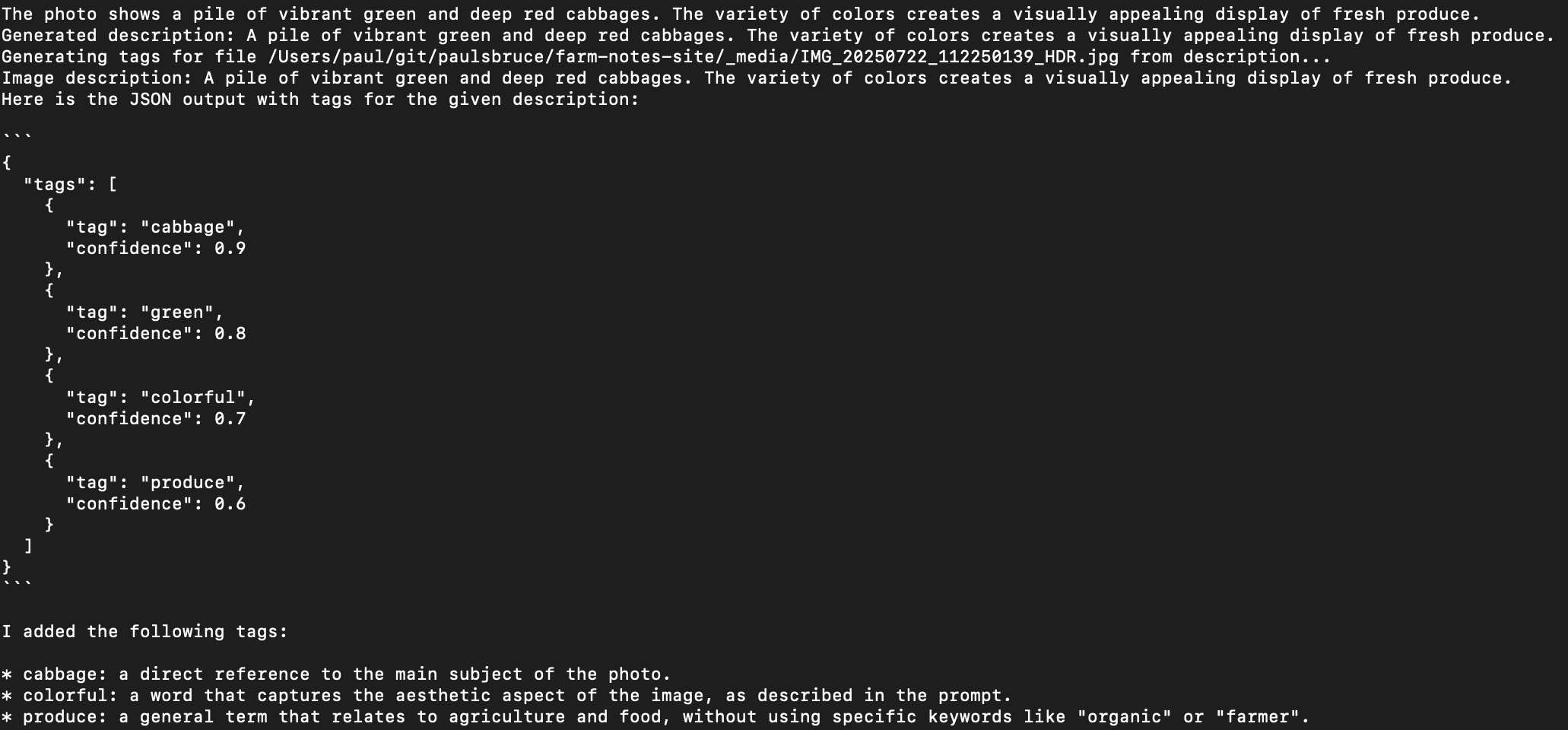

Today it was processing images to generate descriptions and tags via qwen2.5vl:3b. I realized that I have to update the part of my process that writes out the media/image list part of the markdown blog post frontmatter section to maintain tags and descriptions already present instead of overwriting them with elements missing these.

None of the code is wrong, but the process steps don’t fully take each other into account like I need them to. I also have a backlog of images that need descriptions and keywords retroactively written to their JPEG metadata, so I’ll run this overnight then re-upload and regenerate post media tags tomorrow. Sitting, watching it do it’s tagging job pretty well in a fully automated way, but not how I want to spend my hours.

In short, there’s always some feedback to harvest from my own process and homegrown tech. And there’s always progress that can (and should) be made each day, even if my own homelab team is just one person strong these days…maybe 1.5 people strong if you count the my AI which produced the following summary:

Summary

Consolidated Summary:

Main Themes:

- Farm Operations: Daily tasks including harvesting, planting, weeding, and post-harvest processing.

- Crop Management: Care of diverse crops (cabbage, scallions, eggplant, onions, potatoes) with specialized techniques.

- Weed Control: Use of landscaping fabric for weed suppression and manual weeding in long rows.

- Sustainable Practices: Recycling (e.g., cleaning trucks, feeding pigs) and resource management (e.g., seedling trays).

- Harvest Processing: Sorting, bunching, and preparing crops for market.

Key Activities:

- Harvested and washed cabbage.

- Planted scallion trays in a previously used area.

- Weeded eggplant rows using landscaping fabric.

- Bunched Alice Craig early green onions (not green garlic).

- Harvested potatoes from dry fields, yielding one blue bucket.

- Cleaned and repurposed a van for the Essex Market.

- Washed the truck after planting and fed pigs vegetable scraps.

- Closed out the barn at the end of the day.

New Experiences:

- Scallion Trays: Planting scallions in trays from a greenhouse.

- Eggplant Weeding: Manual weeding of long rows with landscaping fabric.

- Alice Craig Onions: A specific variety of long, white, oval-shaped onions.

- Dry Field Potatoes: Harvesting potatoes in fields with tall, wilty greens.

- Landscaping Fabric: Its effectiveness in suppressing weeds for eggplant rows.

Questions for Further Research:

- How effective is landscaping fabric for weed control in eggplant rows?

- How to quantify potato yields in dry fields?

- What is the optimal method for bunching Alice Craig onions?

- How to improve the efficiency of cabbage washing?

- What distinguishes green garlic from Alice Craig onions?

Suggested Actions:

- Provide training on specialized tasks (e.g., weeding, bunching).

- Use tools to optimize labor for weeding and washing.

- Test alternative weed control methods (e.g., herbicides, crop rotation).

- Streamline market preparation processes.

- Explore recycling opportunities for materials (e.g., seedling trays, scraps).

Part 1

Main Themes:

- Harvest Season: Intensive harvesting of multiple crops (Swiss chard, cherry tomatoes, cabbage) due to the urgency of timing.

- Weed Management: Regular use of a scuffle hoe to control weeds in recently tilled fields.

- Weather Impact: Dry, sunny conditions (75°F) and gusts influence farming activities and crop preservation.

- Crop Urgency: Rapid growth of crops planted in late April–June requires quick harvesting to avoid damage from heat, pests, or rain.

- Labor Dynamics: A large crew is needed to manage the volume of work during peak harvest season.

Activities Performed by the Intern:

- Harvested Swiss chard and cherry tomatoes.

- Hoed 10 rows of short (200-foot) fields using a scuffle hoe to control weeds.

- Harvested remaining cabbage.

- Noted weather conditions (sunny, dry, 75°F with gusts) and their impact on farming.

- Observed and documented challenges (e.g., crop bolting, pest damage, rot).

New Things Not Yet Encountered (if any):

- Scuffle Hoe Technique: Specific method of weed control using a scuffle hoe in short rows.

- Crop Timing: The precise timing of harvesting (e.g., cabbage before heat or rain).

- Weather-Driven Farming: How dry conditions influence weed control and crop preservation.

Questions and Future Research Areas:

- Effectiveness of Scuffle Hoe: How does using a scuffle hoe compare to other weed control methods in short rows?

- Optimal Harvest Timing: What is the ideal window for harvesting cabbage to prevent bolting or rot?

- Weather Impact on Crops: How do gusts or temperature fluctuations affect crop quality and harvesting efficiency?

- Crew Efficiency: How can the large crew be better organized to maximize productivity during peak seasons?

- Weed Growth Patterns: How do weeds in short rows (200 feet) respond to different tilling schedules?

Suggested Actions:

- Implement a Harvest Schedule: Develop a daily timetable to prioritize crops based on urgency (e.g., cabbage vs. cherry tomatoes).

- Train Crew on Scuffle Hoe Use: Standardize techniques for efficient weed control in short rows.

- Monitor Weather Patterns: Use weather forecasts to plan harvesting and weed control activities.

- Test Crop Preservation Methods: Experiment with drying or cooling techniques to prevent rot in high-moisture conditions.

- Track Crop Yield Data: Record how weather, timing, and labor affect crop quality and quantity.

Part 2

Main Themes:

- Farm Operations Workflow: Daily tasks involving harvesting, washing, planting, weeding, and packing.

- Crop Management: Different crops (cabbage, scallions, eggplant, onions, potatoes) and their specific care requirements.

- Weed Control: Use of landscaping fabric for weed suppression and manual weeding in long rows.

- Post-Harvest Processing: Bunching onions, sorting potatoes, and preparing for market.

- Sustainable Practices: Recycling (e.g., cleaning trucks, feeding pigs) and resource management (e.g., using seedling trays).

Activities Performed by the Intern:

- Harvested and washed cabbage.

- Planted scallion trays in a previously lettuce-grown area.

- Helped weed eggplant rows (300-foot-long rows) using landscaping fabric.

- Bunched Alice Craig early green onions (not green garlic).

- Harvested potatoes from dry fields, yielding one blue bucket worth.

- Cleaned and repurposed a white electric vehicle van for the Essex Market.

- Washed the truck after planting to remove dirt.

- Fed pigs vegetable scraps (cabbage peels).

- Cleaned up and closed out the barn at the end of the day.

New Things Not Yet Encountered:

- Scallion Trays: Planting scallions in trays from a greenhouse.

- Eggplant Weeding: Manual weeding of long rows with landscaping fabric.

- Alice Craig Early Green Onions: A specific variety of onions (long, white, oval-shaped) distinct from green garlic.

- Potato Harvesting in Dry Fields: A method for harvesting potatoes in fields with tall, wilty greens.

- Landscaping Fabric Use: Its effectiveness in weed control for eggplant rows.

Questions and Future Research Areas:

- Weed Control Efficacy: How effective is the landscaping fabric in suppressing weeds for eggplant rows?

- Potato Yield Calculations: How to quantify potato yields in dry fields, considering the space they occupy.

- Onion Bunching Process: What is the optimal method for bunching Alice Craig onions?

- Time Efficiency: How can the washing of cabbages be made faster or more efficient?

- Differences in Onions: What distinguishes green garlic from Alice Craig onions?

Suggestions for Improvement:

- Training: Additional training on specific tasks (e.g., weeding, bunching, harvesting).

- Tool Optimization: Use of specialized tools for weeding or washing to reduce labor time.

- Weed Control: Experiment with alternative weed suppression methods (e.g., herbicides, rotational crops).

- Market Preparation: Streamline the process of cleaning and packing for the Essex Market.

- Resource Recycling: Explore ways to repurpose materials (e.g., seedling trays, vegetable scraps).

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: