TL;DR

It was a pretty easy day today, a bit hotter than the last but the breeze kept the greenhead flies and mosquitoes away for the most part while we harvested cilantro and weeded a field of peppers and eggplant.

In my homelab and blogging process it was also a bug-free day which is nice when you’re the only one that can support it. Low-variance in a process is sometimes a good thing, though in an incubation engineering model change is always around the corner.

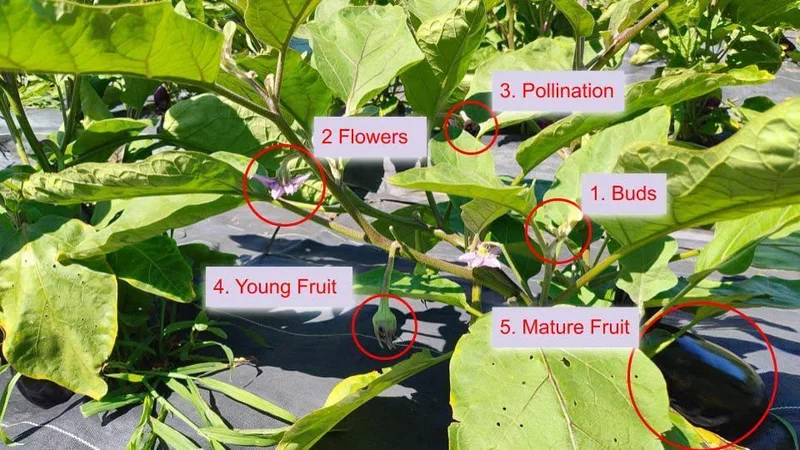

Like an eggplant…plant…at the peak of it’s maturity, all stages of it’s lifecycle are occurring in parallel (as depicted below):

Indeterminate vs. Determinate

A continuous cycle of new growth is what ‘indeterminate’ usually characterizes about the genomic outcomes of a plant [ref]. There are other characterizing differences between determinate (D) and indeterminate (ID) plants. Some determinate plants may exhibit one or two indeterminate characteristics and vice versa. Nature and nurture are both at work in modern species, particularly those bred and cultivated for farming.

As a gardener I used to learn mostly by failure and only occasionally look up what specific terms like ‘determinate’ and ‘indeterminate’ when I wanted to scratch a curiosity itch. I only needed to know these terms at a surface level to buy the right kinds of tomatoes. On a farm with a planting and harvesting schedule, you really have to know what these kinds of terms mean because timing and expected yield is everything.

There’s also a lot of organic chemistry classes I slept through which goes way over my head, but I definitely understand that most dynamics of complex biological systems come with both pros and cons. It’s not too surprising then that the longer a plant grows (flowers, fruits, and produces foliage) the longer it can both produce crop as well as potentially aggregate pests and diseases. In many cases, farmers will have both determinate and indeterminate varieties of high-value crops like tomatoes (in the greenhouse and field) not only for their flavor differences but because of their time-to-market (overlapping early determinate and later indeterminate varieties).

These Eggplants Deserve Hard Workers

These eggplants are (almost certainly) determinate because most eggplant used for farming are bred to be, however many varieties exhibit indeterminate characteristics like continuous new growth too. I checked the seeding schedule but couldn’t find the specific variety, though this farm almost exclusively uses Johnny’s Select Seeds so an educated guess about the specific variety in the below video would be either Nigral, Thanos, or Nadia.

The bees and I were hard at work today making sure that the eggplants are well-off. This is the second time we weeded in this field, despite the landscaping fabric I helped to lay down on May 13th with the rest of the crew that day. More than likely the bees have been at work here since we planted them on May 14th shortly after receiving the bees and situating them in key locations around the fields.

Inspired by how hard the many bees around me were working, I also worked hard to ‘yoink’…as the kids say…so many massive (mostly grass and bind weed) plumes from the unused holes in the landscape fabric and around the base of the eggplants. What once was a jungle of threat to the eggplants is no longer, at least until next month.

If there is time amongst all the priorities next week, the only chore left is to move all the pulled weeds currently left in the aisles between plant rows to the outside of the field. After they loose most of their biomass to drying in the hot and bright sun for a few days, this is worth doing because dead greens can easily harbor bugs and spores. Its also a nuisance to deal with dirt and biomass clumps when taking up the landscaping fabric at some point either at the end of the season or most certainly early next spring.

When It Works, Don’t Touch It?

Today, my blogging process components worked like a charm, mostly because of the ‘weeding’ I did earlier this week. All of them are built purposely automation ready, but the end-to-end process I’m still…micro-managing…purposely because I’m still tweaking the data contracts and intra-process hand-offs on a frequent basis. Like indeterminate species of plants, I am continuously producing new growth, as is my daily process on the farm.

The thing about us software ‘engineers’, if something works you absolutely MUST take it apart and make it better. So this weekend, I’ll likely spend a chunk of ‘fun’ time hardening the steps and distilling them into some sort of concoction involving local Gitlab workflow(s) and Github Actions to:

- Ultimately create a temporary branch and PR with site preview in Netlify, when…

- All inputs (notes, images, and maybe even human-content draft) are available

- Only once all testable proofs (including images, links, and spellings) pass should it automatically merge to main and kick off the usual publishing process

For today, it remains semi-automated because during the week I’m busy dodging bees and declassifying my ignorance over common agricultural terms like ‘indeterminate’.

AI-generated Summary from Field Notes

Main Themes:

- Weather: Hot day (80–85°F) with cool morning, affecting work pace and comfort.

- Crew Size: Smaller team (4 people) limited heavy tasks like harvesting.

- Preparation: Sanitation of bins, tools, and buckets.

- Harvesting: Cilantro harvesting for ~1 hour.

- Weeding: Managing weeds in landscaping fabric-covered rows and walkways.

- Task Prioritization: Balancing urgent tasks (harvesting, loading) with routine weeding.

- Resource Management: Reusing landscaping fabric to minimize waste but facing challenges with weeds in unused areas.

Activities Performed:

- Washed bins, knives, and buckets for sanitation.

- Harvested cilantro for ~1 hour.

- Weeded rows in fabric-covered areas, focusing on unused holes and walkways.

- Prepared trays for the greenhouse and loaded the truck with assistance.

- Helped load the truck, moving trays to the barn for shade.

- Documented observations on weed growth and fabric usage.

New Things Not Encountered:

- Weed Species: Specific types of weeds in unused holes vs. planting holes.

- Fabric Management: Techniques for reusing fabric and addressing exposed dirt.

- Weeding Challenges: Impact of weeds in walkways and off-row areas.

- Workload Balancing: Efficient task prioritization under heat conditions.

- Tray Handling: Streamlining tray preparation and loading to reduce strain.

Questions for Research:

- How to effectively manage weeds in unused holes of landscaping fabric?

- What is the optimal schedule for weeding walkways and off-row areas?

- How to minimize time spent on weeding while maintaining effectiveness?

- How does heat affect task completion and worker comfort?

- What techniques can optimize tray handling to reduce physical strain?

Suggested Actions:

- Monitor Fabric Usage: Track weed growth in unused holes and adjust fabric placement.

- Implement Regular Weeding: Create a schedule to address weeds in walkways and off-row areas.

- Train on Efficient Weeding: Teach techniques to reduce time spent on weeding.

- Optimize Tray Handling: Streamline tray preparation and loading processes.

- Document Weather Impact: Record how heat/humidity affects task efficiency and worker comfort.

Part 1

Main Themes:

- Weather Conditions: Hot day (80–85°F) with cool morning, impacting work pace and comfort.

- Reduced Crew: Smaller team (4 people) due to fewer workers, limiting heavy tasks like harvesting.

- Preparation and Sanitation: Cleaning bins, tools, and buckets to maintain hygiene.

- Harvesting: Cilantro harvesting for ~1 hour.

- Weeding: Managing weeds in landscaping fabric-covered rows, focusing on unused holes and walkways.

- Task Prioritization: Balancing urgent tasks (harvesting, loading) with routine maintenance (weeding).

- Resource Management: Reusing landscaping fabric to minimize waste but facing challenges with weeds in unused areas.

Activities Performed by the Intern:

- Washed bins, knives, and buckets for sanitation.

- Harvested cilantro for ~1 hour.

- Weeded rows in landscaping fabric-covered areas, focusing on unused holes and walkways.

- Prepared trays for the greenhouse and loaded the truck with assistance.

- Helped load the truck with two people, moving trays to the barn for shade.

- Documented observations about weed growth and fabric usage.

New Things Not Yet Encountered:

- Weed Species: Specific types of weeds (e.g., those in unused holes vs. planting holes).

- Landscaping Fabric Management: Techniques for reusing fabric and addressing exposed dirt.

- Weeding Challenges: The impact of weeds in walkways and off-row areas.

- Workload Balancing: Strategies for prioritizing tasks when the crew is small.

- Tray Management: Efficient methods for seating trays in the greenhouse and barn.

Questions for Future Research:

- Weed Control: How effective is landscaping fabric in controlling weeds, and what are the best practices for managing exposed dirt?

- Weed Species: Are there specific weed species that thrive in unused holes, and how do they differ from those in planting holes?

- Weeding Timing: What is the optimal time to perform weeding (e.g., before or after planting) to minimize weed growth?

- Crew Efficiency: How can a smaller crew manage tasks like weeding and loading without compromising productivity?

- Fabric Reuse: What are the long-term impacts of reusing landscaping fabric, and how can it be optimized for weed suppression?

Suggested Actions:

- Monitor Landscaping Fabric: Track weed growth in unused holes and adjust fabric placement as needed.

- Develop Weeding Schedule: Create a regular weeding schedule to address weeds in walkways and off-row areas.

- Train on Efficient Weeding: Teach team members techniques to minimize time spent on weeding while maximizing effectiveness.

- Optimize Tray Handling: Streamline tray preparation and loading processes to reduce physical strain on the crew.

- Document Weather Impact: Record how weather conditions (e.g., heat, humidity) affect task completion and worker comfort.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: