TL;DR

A pretty typical day on the farm, greenhouse watering and egg washing and tis the season to be planting (onions this week). But I also took time to record some audio notes about a conceptial robotic watering system.

Typical Day on the Farm

Between late March and June, the greenhouse needs to be watered at least once if not twice a day (later on in the season). This takes around 45 minutes to one hour each time, and a breakdown by season goes as such:

- March - one watering in the morning per day; 21 days

- April - two waterings, one in the morning and one mid-day; 30 days

- May - two waterings, 31 days

- June - two waterings; 30 days

- July and August - little use since it’s too hot even with climate control

- September - two waterings; 21 days

This is approximately 133 days each year, and in the early season when there’s lots to do elsewhere, is around 12-15 hours per week for one person. More on this later.

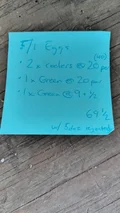

Egg Washing Metrics

Egg washing happens twice a week. Eggs are collected every day and batched up in the walk-in fridge until washing day (usually Monday and Thursday). Yesterday I processed 70 dozen in about 4.5 hours with about 5 dozen rejected (between 5 and 10 percent loss due to cracks or broken is expected). Reasons for defects are mostly handling issues, thin shelled eggs, or internal pressure changes when going from fridge to warm water wash. It’s rare that the final ‘polishing’ phase is the cause of rejection.

More Onions in the Dry Field

After lunch, we planted another row of yellow onions. In total this week, we planted about 8500 onion starts. Each row takes about 13-14 98-cell trays at a 6-inch spacing in a 4 foot wide row that is around 200-250 feet long. The soil at the ends of each row are typically compacted by the tractor so it’s a bit more work to plant into that area.

Many people think of onions as a commodity / staple crop and turn their noses up at prices that don’t compare to mega-mart prices. As supply chain and input costs go up, even those prices are going up while local farms aren’t as affected (unless they rely on a lot of inputs). We plany at least three types of onions…all of which are sweet, earthy, and worth adding to the CSA member bags even if they are just a few per week.

What can you do with farm-fresh onions that aren’t a waste of their gorgeous flavor? I’ll be adding many recipies as the season progresses, but for now here are some quick ideas:

- fine dice a quarter of an onion and mix with oil, orange juice, and other herbs to make a salad dressing

- slow cook a few down until carmelized and put on burgers, hot dogs and sausages

- quick pickle them with a splash or two of red wine vinegar and use on tacos

- thinly slice and separate to sprinkle over homemade pizza

The onion you pay for (or plant yourself) is the onion you deserve.

Watering Robot (Concept)

As I was watering this morning, I started to think about how to automate (most) of the process. We use a wand hose attachment and it’s not hard work. Hand-watering also allows you to make visual inspections and pay more attention to specific areas where either some plants are more water-hungry than others or watering was missed otherwise.

There are no new ideas…really?!

I know there are many systems already and in particular ones that require permanent installation of sprayers and drip emitters with hose running throughout the greenhouse rafters. While mostly effective, these broad-stroke systems can often miss and either over or under water parts of the greenhouse since there’s no intelligence or ability to dial-in specific areas based on need. Yes you can turn up or down the flow rate of certain spots, but then no matter what, you end up optimizing where you put trays based on what the watering system is configured to do. Ultimately, these systems are permanent and relatively static…and usually cost a lot of money.

So if there was an alternative solution, the features and success factors might be something like:

- Significantly lower in cost than commercial greenhouse watering systems

- Less or equal effort to install, maintain, and repair the operational status throughout the season

- Most of the mechanical and hydro parts are stock, can be purchased independently of the “brains” or “hub”

- Reduction of water use and waste, or increase in water re-use

- Controllable and (re)configurable easily, maybe by a mobile app

- Adaptive based on what is constantly being changed and moved around in the greenhouse

- Learning and precise: gets better at managing specific needs of particular trays, plants, and their demand

- Conditional based on weather (temperature/humidity) and specifically sunlight (which dramatically changes greenhouse conditions)

- Quantitatively shows condition and resource (power, water) usage over time

- Predictive: shows projected future costs and adjust predictions with simple human-suggested upcoming changes

- Communicative: push notification and alerts of things like abrupt changes, malfunctions, etc.

- Observable: tracks specific trays and visualizes growth over time to provide drill-down capabilities in app

Early Concept Design

In my mind, I see it as a ‘robot’ (or two) suspended by two wires that strech end-to-end under the ridge line of the greenhouse…using pulleys kind of like those on the end of an old clothesline. It has a high-pressure nozzle (or two) and a counterweight arm pointed downward. The connected hose is retractible and also suspended from the wire(s), depressurized upon retraction movements. It has cameras for images and video capture. It has on-board sensors for collecting various conditions like humidity (really vapor pressure deficit) and temperature.

It intelligently waters things based on plant size, species and recency of encountered status. It reports problems such as unexpectedly low or dropped water flow rate and online/offline status. It suggests when manual spot-watering might be better and holds off if configured tolerance for safety is high enough. It may have an on-board battery that can be recharged at the base station using solar energy.

The only ‘for purchase’ part is the robot itself and the kit of everything else can either be purchased directly or cobbled together with in-spec parts from your local hardware store. Installation should be easy, but can be assisted remotely by a registered/trained technician upon request.

This can also be installed over a garden outside since the parts are all weatherproof and durable in non-freezing conditions. So the market wouldn’t just be greenhouses (primary) but also specialty market gardens.

Low-Cost, Low-Tech, Low-Code

Like other low-cost farming solutions such as the CoolBot, I want this to be something that experimental farmers can prove out first because conventional farmers often have an aversion to ‘new’ (unproven) ways of doing things, for good reason. Everything on a farm is a bet with varying risk levels, even proven and traditional approaches because nature is unpredictable. So anything that takes more micro-managing is usually a solid ‘no’ from farmers who are already juggling many things throughout the season.

The day-to-day usage should be easy for the average mobile app user to pick up quickly. It shouldn’t require a conversation or a credit card to spec out and budget for. It should have plenty of testimonials from early adopters to make the case for it, not a bunch of marketing blah blah. It should be flexible enough where a non-coder can customize various aspects of system behaviors, with the most common customizations being features, but also with extensibility via code at the forefront of each feature.

A Big Middle Finger to Big AgTech

I also want this to be in direct opposition to proprietary, licensed/subscribable, AgTech…and specifically support the ‘Right to Repair’ movement. Maybe it could be added to FarmHack or possibly open-sourced elsewhere, but definitely should be stuff that a tech-savvy person can run themselves without needing to rely on a 3rd-party SaaS or be dependent on a for-profit licensing or subscription service.

It should be runnable all by itself, only requiring a mobile device (such as a phone that farmers have on them already) for advanced features such as scheduling and behavior adjustment. For advanced data scenarios such as backing up video and images it takes, it should be able to connect to a ‘home server’ and/or a cloud service without incurring a license fee.

Of course, the software and various installations would require occasional assistance by support and a ‘product team’ consisting of developers, product owner(s), and DevOps/SRE for the simplified cloud-hosted stuff. I think there’d be enough demand for the ‘not self-hosted’ thing compared to the ‘community/core’ version.

Is this a business model? Yes. Is it a business model that attracts moron investors? No.

AI Isn’t the Only Game in Town

Creativity isn’t a uniquely expert or human experience. Like “The Creative Thinker’s Toolkit” suggests, intentionally conflating unrelated ideas can often lead to interesting avenues of further thought. Recently, large language models (LLMs) have taken much of the populist technology savant’s attention because it distills a massive amount of information into reusable models for generating various outputs.

What it doesn’t do (yet) is intentionally conflate adjacent concepts in a way that isn’t interpreted as ‘hallucinations’. Later this year after the growing season is over, I plan to revisit this potential, employing concepts from pragmatic creative processes using the homegrown LLM and RAG system I’ve been tuning with this blog. For now, this is what my ‘intern research analyst’ level system thinks I did with my day. \

At least it chunked out the transcript to documents that are grouped by theme, which was cool. Still I think a multi-modal interpretation of the transcript (narration of day vs. development of an idea), identifying the nature of the dialog, then applying specific templates for summary based on intent would be more efficient.

Main Themes:

- The hydroponic system and its complexities

- Design considerations for the greenhouse robot

- Daily farm work and tasks performed by the intern

Activities Done by the Intern:

- Watering the greenhouse using a hydroponic system

- Washing eggs

- Planting yellow onions in dry fields (with three other team members)

New Things Not Yet Encountered:

- The hydroponic system’s complexities, particularly with pressure, flow rate, and mechanical control

- The robot’s potential uses and design considerations for the greenhouse

Questions and Future Areas of Research:

- How to address the challenges of the hydroponic system, such as pressure, flow rate, and water kickback?

- How to design a practical and efficient arm extension mechanism for the robot

- How to ensure safe and easy interaction with the robot while working in the greenhouse

Suggestion Actions:

- Conduct further research on the hydroponic system’s complexities and explore potential solutions.

- Design and test the proposed arm extension mechanism for the robot.

- Consider conducting more experiments or simulations to validate the effectiveness of the hydroponic system and the greenhouse robot.

Overall, the intern seems to be enthusiastic about the project and has some initial ideas and questions about how to address the challenges of the hydroponic system and the greenhouse robot.

Part 2 (Automatically Grouped to Product Design by LLM)

Main Themes:

- The challenges and inefficiencies of manual watering systems in greenhouses

- The potential for automation and robotics to improve efficiency and reduce labor costs

- The intern’s curiosity about new technologies and innovative solutions

- The importance of considering economic feasibility when evaluating new ideas

Activities the Intern Did:

- Watered the greenhouse (about 2 hours a day, 10 hours a week)

- Observed automated watering systems in greenhouses

- Thought about designing a robot to automate watering

- Brainstormed potential features for the robot (sensors, cameras, jet spray)

New Things Not Yet Encountered:

- Automated greenhouse watering systems with robots

- Drip emitters and spray emitters

- Pulley systems with thin wires

Questions and Future Areas of Research:

- How to design a robot that can efficiently water the entire length of a greenhouse

- How to power and recharge the robot (onboard battery or cord)

- How to ensure reliable communication between the robot and the base station

- How to address potential issues with the robot, such as breaking down or needing maintenance

Suggested Actions:

- Conduct further research on automated greenhouse watering systems and robotics

- Design and build a prototype of the proposed robot

- Test and evaluate the efficiency and effectiveness of the robot in a real-world setting

- Consider hiring help to assist with the robot’s development and deployment

- Evaluate the economic feasibility of implementing the robot on a larger scale, considering labor costs and potential savings.

[end of post]

Enjoy Reading This Article?

Here are some more articles you might like to read next: